UN Sustainable Development Goals

Promote inclusive and sustainable economic growth, employment and humane work for all

Rigid polyurethane foam is particularly efficient when it comes to protecting buildings from heat and cold, and it keeps food fresh from the harvest all the way to the table when used as an insulating material in refrigerating equipment. Covestro manufactures the key building blocks for this product, including methylene diphenyl diisocyanate (MDI). Because the material is in such demand, the company is currently expanding its global production.

Tarragona in Spain is one of the expansion sites. We are also building a chlorine plant here, because chlorine plays a vital role in the production of MDI. However, its manufacture consumes a great deal of energy – and that means high costs. Help is at hand in the form of an innovative process developed to market maturity by Covestro and thyssenkrupp Uhde Chlorine Engineers: oxygen-depolarized cathode (ODC) technology, which is being deployed for the first time in an industrial-scale plant in Tarragona. This technology reduces the voltage required for the manufacturing process from three to two volts – one vital volt less.

“There were three key success factors in our development of ODC technology: trust, complementary skills and a common vision,” says Denis Krude, CEO of thyssenkrupp Uhde Chlorine Engineers. “It took great perseverance and real groundwork to jointly develop a product from the germ of an idea all the way to series production. And we’ve taken a groundbreaking step towards greater sustainability.”

“Germany’s annual energy consumption would fall by around one percent if chlorine were manufactured across Germany using ODC technology. That would require a high level of investment,” explains Dr. Hanno Brümmer, who is Head of Production at the Polyurethanes segment at Covestro and responsible for global chlorine production. “But the savings would be roughly equivalent to a year's electricity consumption in a big city like Cologne, Germany.”

Baytown

Baytown (USA)

Project: Construction of a new large-scale plant for the rigid foam precursor MDI. At 1.5 billion euro, it marks the single biggest investment in the history of Covestro. The company hopes to benefit from significant growth in the MDI market.

Planned completion: 2024

South Deerfield

South Deerfield (USA), Map Ta Phut (Thailand), Guangzhou (China), Dormagen (Germany)

Project: Expansion of global film production to meet rising demand in all regions. These high-quality semi-finished goods are used in the automotive, medical equipment and security card sectors, among others.

Planned completion: 2019 / 2020

Rotterdam

Rotterdam (Netherlands)

Project: Covestro and its joint venture partner LyondellBasell are incorporating an innovative technology into an existing production plant to convert water-based waste into energy and reduce the plant’s CO2 emissions considerably.

Planned completion: 2020

Antwerp

Antwerp (Belgium)

Project: Aniline production is being expanded considerably as part of the global MDI investment program, strengthening Antwerp’s position as the European center for aniline. The chemical is also required for the manufacture of the rigid foam precursor MDI.

Planned completion: 2022

Tarragona

Tarragona (Spain)

Project: Expansion of MDI production capacity and construction of the company’s own chlorine production facility. This first industrial- scale chlorine production plant is based on particularly energy-saving ODC technology.

Planned completion: Chlorine production: 2020 / MDI: 2022

Brunsbüttel

Brunsbüttel (Germany)

Project: Construction of a new MDI plant. Ultimately production capacity will double to 400,000 metric tons per annum. That will make Brunsbüttel one of the largest MDI production sites in Europe.

Planned completion: 2019

Dormagen

South Deerfield (USA), Map Ta Phut (Thailand), Guangzhou (China), Dormagen (Germany)

Project: Expansion of global film production to meet rising demand in all regions. These high-quality semi-finished goods are used in the automotive, medical equipment and security card sectors, among others.

Planned completion: 2019 / 2020

Leverkusen

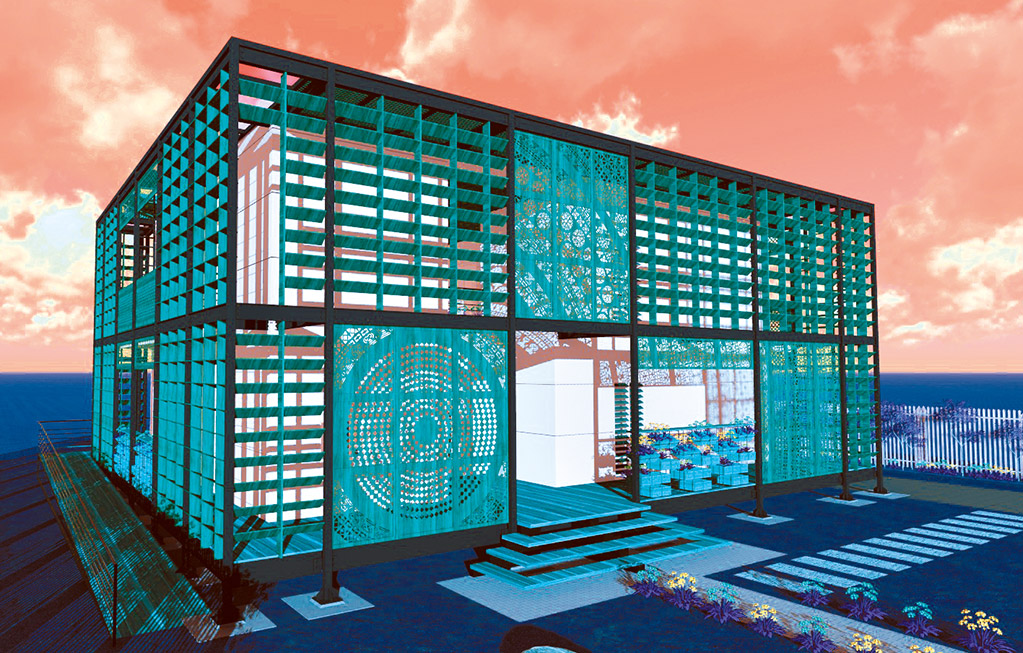

Leverkusen (Germany)

Project: Construction of a new administrative building at the Leverkusen head office. This will provide new job opportunities for some 700 Covestro employees.

Planned completion: 2019 / 2020

Guangzhou

South Deerfield (USA), Map Ta Phut (Thailand), Guangzhou (China), Dormagen (Germany)

Project: Expansion of global film production to meet rising demand in all regions. These high-quality semi-finished goods are used in the automotive, medical equipment and security card sectors, among others.

Planned completion: 2019 / 2020

Shanghai

Shanghai (China)

Project: Covestro is responding to strong demand in Asia-Pacific with expanded polycarbonates production. The new capacities will be increased one step at a time and be available starting in early 2019.

Planned completion: step-wise from 2019

Map Ta Phut

South Deerfield (USA), Map Ta Phut (Thailand), Guangzhou (China), Dormagen (Germany)

Project: Expansion of global film production to meet rising demand in all regions. These high-quality semi-finished goods are used in the automotive, medical equipment and security card sectors, among others.

Planned completion: 2019 / 2020

Investments around the globe

Covestro sees considerable potential for growth in the years to come and intends to expand production accordingly. For this reason, the company is investing and building around the globe. The precursor here is MDI – a key building block for the rigid foam used as a highly efficient insulating material in buildings and refrigerators.